DTF technology

What is DTF Printing?

DTF (Direct-to-Film) printing is a revolutionary textile printing technology that enables vibrant, durable and flexible designs on a wide variety of textile materials. Unlike traditional, previously known printing methods such as screen printing or DTG (Direct-to-Garment) printing, DTF printing requires no pre-treatment and works easily on light and dark fabrics, as well as on various materials such as cotton, polyester, blended fibers.

How does DTF printing work?

The DTF process consists of a few simple but highly effective steps:

- Edit graphics: Create the design you want to print in a graphics program (Canva, Photoshop, Illustrator, etc.) and then prepare it in a printable file format.

- Print on foil: Open the file in your RIP software and print the graphics onto the special DTF film with vibrant, pigment-based inks.

- Powder application: After printing, a special adhesive powder must be applied to the print, this can be done manually or if you have an automatic printing system, the drying unit will do it for you.

- Curing: Powder coated prints must be allowed to pass through the drying unit at the appropriate temperature so that the powder melts, absorbs the dye pigments and then dries, if you have a printing system this will also be automatic.

- Transfer: Place the film on the material and transfer the pattern with a heat press. We recommend setting it to 165°C and 15 seconds. Depending on the type of DTF film, peel it off cold or hot and the labeled product is ready.

Why choose DTF printing?

- Works on a variety of fabrics – DTF printing is not limited to certain fabric types, it can be used on cotton, polyester, blended fabrics, and even leather or canvas.

- No pre-treatment required – Unlike DTG printing, there is no need to pre-treat the fabric, further reducing production time and costs.

- Durability and washability – DTF prints are extremely durable, resistant to cracking, fading, and peeling, and can last up to 60-70 washes with proper care.

- Cost-effective for both small and large quantities – Ideal for mass production and one-off custom pieces, making it perfect for print-on-demand businesses.

- Vivid and detailed prints – With vibrant colors, sharp details, and soft-touch surfaces, DTF provides superior print quality compared to many other methods.

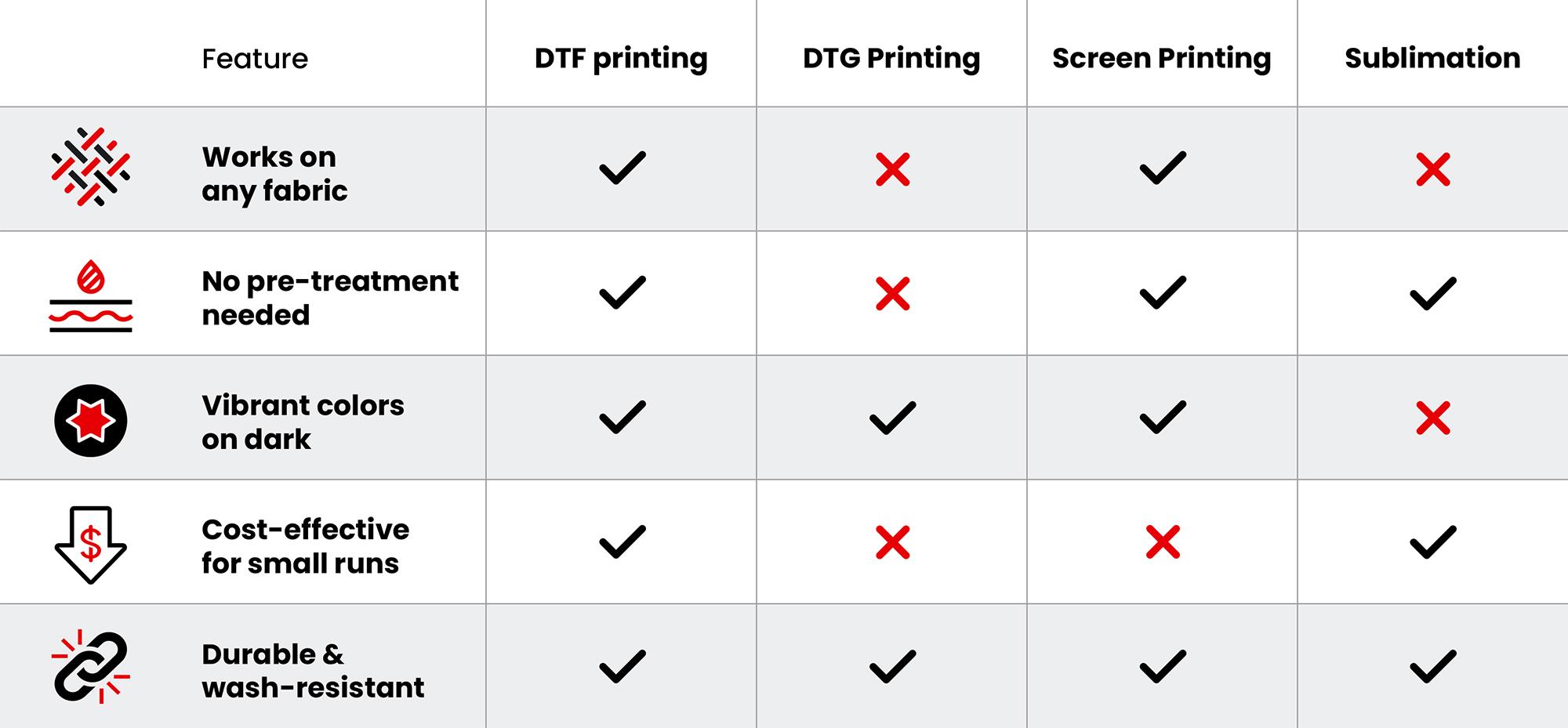

Compared to other textile customization technologies DTF (Direct-to-Film) printing stands out from other printing technologies due to its versatility, ease of use, and cost-effectiveness. Unlike DTG (Direct-to-Garment) printing, which works best only on cotton and requires pre-treatment, DTF printing can be applied to almost any fabric without the need for pre-treatment. This means you can print on cotton, polyester, blends, and even non-textile surfaces effortlessly.

Compared to sublimation printing, which is limited to white or light-colored polyester fabrics, DTF printing allows you to create vibrant designs even on dark fabrics without the need for a special coating. Screen printing is a great solution for mass production, but for small to medium production runs, DTF is far more cost-effective, as it doesn’t require high setup costs or specialized screens.

Additionally, DTF printing delivers long-lasting and wash-resistant results, ensuring your designs stay vivid and intact after multiple washes. This makes it an excellent choice for businesses looking for a flexible, high-quality, and efficient printing solution.

How to decide which type of DTF printer will suit the best for your business

When selecting a DTF printer, it's essential to consider factors such as print width, speed, and production capacity to align with your business needs. At Unity Printer, we offer a range of DTF printers tailored to various requirements:

- Unity DTF Printer 33-216: This model features a maximum printing width of 300 mm and a printing speed of 6 m²/hour in 6-pass mode. It's equipped with two Epson i1600 print heads and includes Flexi Photo Print RIP software. The package comprises the printer, powder machine, table stand, RIP software, a 12-month warranty, and a 6-month warranty for the print heads.

- Unity DTF Printer 60-232: Designed for larger-scale operations, this printer offers a maximum printing width of 600 mm and a printing speed of 9 m²/hour in 6-pass mode. It utilizes two Epson i3200 print heads and comes with Flexi Photo Print RIP software. The price includes the printer, powder machine, RIP software, a 12-month warranty, and a 6-month warranty for the print heads.

In addition to selecting the right printer, using high-quality consumables is crucial for achieving vibrant and durable prints. Unity Printer provides a comprehensive range of premium DTF consumables:

- DTF Inks: Our pigment-based inks are formulated to deliver vivid colors and excellent adhesion, ensuring your designs stand out and last.

- DTF Films: We offer specially coated PET films that facilitate smooth ink transfer and precise image reproduction, essential for detailed and complex designs.

- DTF Powders: Our adhesive powders are designed to work seamlessly with our inks and films, providing strong bonding and enhancing the durability of the final print.

By combining the appropriate DTF printer with our high-quality consumables, you can ensure efficient production and exceptional print results, positioning your business for success in the competitive custom apparel market.

Start printing with DTF today!

DTF technology is an excellent choice for businesses looking to expand their customization services or streamline production. Whether you run a print shop, a fashion brand, or an online merchandise store, DTF offers a profitable and easy-to-use solution for creating high-quality printed apparel and promotional products.

At Unity Printer, we provide premium DTF printers, inks, films, powders, and shakers to help you achieve consistent, professional results.

Explore our DTF printing solutions today and take your business to the next level!